MVB completes first Beckton shaft sinking

12 October 2011A contracting JV of Morgan Sindall, Vinci Construction Grands Projets and Bachy Soletanche has completed the first of three shafts at Beckton in east London for the construction of Thames Water’s Lee Tunnel sewerage project.

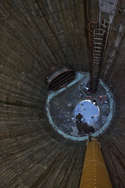

The shaft is 20m in diameter and 75m deep. Recent work on it included the installation of a 4.5m-thick, domed base slab. The next step is to form the final concrete lining by slip-forming. The shaft is presently supported by diaphragm walls, 1.5m thick, and 90m deep to go below the shaft base. It was constructed to a vertical tolerance on only 0.3 per cent (approx. total permissible deviation of 270mm).

The project, valued at GBP 635M (USD 994M) and the largest awarded in the UK water services industry since its privatisation in 1989, was designed to help prevent 16 million tonnes of sewage per year from entering the River Lee as overflow during times of heavy rainfall, capturing the discharge from the Abbey Mills Pumping Station in Stratford.

The 7km (4.3-mile) long Lee Tunnel itself will be 7.0m in diameter, run up to 75m deep, and will carry flow to the Beckton water treatment works, which will be expanded by 60 per cent in capacity to deal with the extra flow.

Other shaft work progress at the Beckton site includes completion of 98m-deep diaphragm walls for the pumping shaft. This shaft’s finished diameter will be 38m and the diaphragm walls are 1.5m thick. The 92m-deep diaphragm walls for the 25m-diameter connection shaft are also complete.

At Abbey Mills work is underway on the 25m-diameter, 68m-deep shaft that will receive both the Herrenknecht TBM and, on project completion, the sewage flow. This shaft is being constructed with 1.2m-thick, 83m-deep diaphragm walls.

Other ground preparation work being carried out at the Beckton site includes jet grouting at the Beckton Culvert, plus permeation grouting for fissure sealing in the chalk with flints at the TBM breakout and in a ‘curtain’ 11m below the diaphragm walls. This is all designed to prevent any groundwater leakage during tunnelling start-up. The Herrenknecht slurry-shield TBM, named ‘Busy Lizzie’ by a local schoolboy, will be launched in the New Year. The expected progress rate is 17m per day.

Work will begin soon on full-scale testing of the precast concrete tunnelling lining segments in situ.

The tunnel is now due for completion in 2014.

CH2M Hill is programme manager for the whole Thames Tideway scheme and key technical adviser to Thames Water is AECOM.

Looking down the Beckton overflow shaft during work on the domed base slab. Note diaphragm wall shaft lining and TBM inset